In the ongoing era of industrial automation, where precision, efficiency, and reliability define competitiveness, even the smallest components play a crucial role in ensuring the smooth and continuous operation of production systems. Among these unsung heroes of automation, drag chains—also known as cable carriers or energy chains—stand out as indispensable elements in protecting cables and hoses that power the motion of modern machines.

As factories evolve toward smart manufacturing, and as robotic systems, CNC machinery, and automated assembly lines operate at unprecedented speeds, the expectations placed upon drag chain technology have also undergone a fundamental transformation. This article explores how drag chains are adapting and upgrading in response to the rapid evolution of industrial automation.

1. The Growing Demands of Industrial Automation

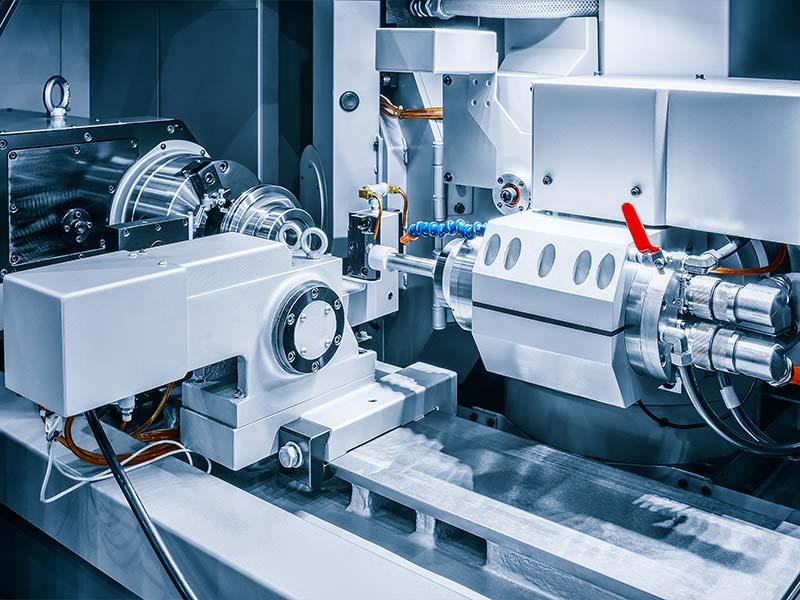

Industrial automation has transformed from simple mechanical assistance to an interconnected digital ecosystem. Modern manufacturing relies heavily on robotics, sensor systems, and precision motion control, requiring cables and hoses to perform dynamic movements over millions of cycles without failure.

Traditional drag chains, designed merely to prevent cable tangling or wear, are no longer sufficient. They now must meet higher mechanical endurance, reduced noise levels, enhanced energy efficiency, and integration with smart monitoring systems.

The rise of Industry 4.0 and smart factories means that machines are constantly communicating, adjusting, and optimizing. The components enabling these movements—such as cables, hoses, and drag chains—must evolve from passive mechanical parts into intelligent, data-aware, and durable protection systems that support the overall digital ecosystem.

2. What Makes a Modern Drag Chain “Smart”?

The term “smart drag chain” might sound futuristic, but it’s already becoming a reality. Traditional cable carriers served a purely mechanical function: to guide and protect moving cables. However, in today’s high-tech environment, manufacturers are integrating sensors, advanced materials, and predictive monitoring technologies into their drag chain designs.

Modern drag chains now feature embedded wear sensors and load detectors that can monitor strain, bending radius, and internal temperature in real time. This allows predictive maintenance before a failure occurs—an essential capability for high-value automated systems where downtime is costly.

Some systems even communicate with central control units via IoT protocols, sending data on chain condition, cable movement frequency, and vibration levels. Through this, the drag chain becomes part of a cyber-physical system, contributing to the machine’s self-diagnostic and maintenance intelligence.

3. Material Innovation: From Steel to Advanced Polymers

The evolution of drag chains is also marked by significant advancements in material science. Early drag chains were typically made of steel or aluminum, offering durability but adding considerable weight and requiring regular lubrication.

Today, the industry trend leans heavily toward high-performance engineering plastics. Modern polymer-based drag chains combine light weight, high tensile strength, impact resistance, and corrosion-proof properties—making them ideal for harsh industrial environments.

These polymers are often reinforced with glass fibers or carbon composites, providing structural rigidity without compromising flexibility. Unlike metal chains, plastic drag chains operate quietly, require no lubrication, and are resistant to chemicals and humidity. This transition has not only reduced maintenance costs but also enabled drag chains to perform reliably in cleanroom, food processing, and pharmaceutical applications where metal contamination or oil residue is unacceptable.

4. Precision Engineering and Modular Design

As machine designs become more customized and compact, drag chain manufacturers have responded with modular and precision-engineered designs.

Modern drag chains are built with modular link systems, allowing users to easily adjust the chain length, replace damaged sections, or add separators to organize cables and hoses efficiently. Some designs use openable crossbars that can be detached without tools, drastically reducing assembly and maintenance time.

In addition, noise reduction has become a design focus. Advanced drag chains feature optimized link geometry and integrated damping elements that minimize vibration and operational sound. This is particularly valuable in high-speed CNC machining centers and robotic automation where acoustic comfort and precision are crucial.

Moreover, drag chain geometry is now optimized for minimal friction and smooth motion, ensuring stable operation even under heavy loads or long travel distances. The result is higher reliability, longer service life, and consistent performance in demanding automation environments.

5. Customization for Industry-Specific Needs

Industrial automation is not a single system—it encompasses multiple sectors such as automotive manufacturing, electronics assembly, logistics automation, and renewable energy. Each of these industries imposes unique requirements on cable carrier systems.

In automotive assembly lines, drag chains must handle long horizontal movements while resisting oil, heat, and metal debris. In robotic welding systems, they must provide flexibility for multi-axis movement while enduring high temperatures and electromagnetic interference.

Meanwhile, semiconductor and electronics manufacturing demands ultra-clean, anti-static drag chains to prevent contamination and protect sensitive circuits. Offshore and renewable energy applications require corrosion-resistant, UV-stable chains capable of operating under extreme weather conditions.

To meet these diverse challenges, manufacturers now offer highly customizable drag chain solutions—from selecting the right material composition and internal cable layout to integrating strain relief modules or fluid lines. This degree of customization ensures optimal compatibility between the drag chain and the machine it serves.

6. Integration with Digital Manufacturing Systems

The next major leap in drag chain evolution lies in its integration with digital manufacturing ecosystems. In smart factories, every machine component contributes to the flow of information that enables predictive maintenance and process optimization.

By incorporating RFID tags, condition monitoring sensors, or optical fibers, modern drag chains can relay operational data to centralized control systems. This data helps maintenance engineers track movement cycles, detect anomalies, and schedule timely replacements before a breakdown occurs.

Furthermore, advanced CAD/CAM integration now allows engineers to simulate drag chain behavior during the machine design phase. Virtual modeling can predict bending stresses, travel limits, and cable interference—eliminating potential design flaws before production even begins.

This digital twin approach aligns perfectly with the goals of Industry 4.0, enabling seamless coordination between physical equipment and its virtual model for enhanced reliability and efficiency.

7. Sustainability and Energy Efficiency

Sustainability has become a defining value in modern manufacturing, and drag chain technology is evolving accordingly. The use of recyclable polymer materials, lightweight designs, and lubrication-free operation all contribute to reducing a system’s environmental footprint.

Lighter drag chains reduce the energy needed to move machine components, especially in long-travel applications. In addition, maintenance-free materials eliminate the need for oil or grease, minimizing contamination and waste.

Many manufacturers are now adopting closed-loop recycling systems for worn-out drag chains, reusing high-grade polymers to create new products. This eco-conscious approach not only reduces waste but also aligns with global sustainability standards such as ISO 14001 and ESG-oriented manufacturing principles.

8. Future Outlook: The Intelligent Drag Chain

Looking ahead, drag chains are expected to evolve from simple mechanical guides into active, intelligent components of automated systems.

Emerging designs are experimenting with self-diagnosing materials, where embedded micro-sensors detect stress distribution, temperature changes, or chemical exposure in real time. Combined with AI-driven maintenance algorithms, this could allow fully autonomous condition monitoring.

In addition, hybrid drag chain systems—combining mechanical flexibility with embedded electronic circuits—may soon become part of data transmission networks themselves, helping manage both power and communication signals within moving systems.

The future drag chain will not only protect but also communicate, optimize, and adapt, supporting the transformation of industrial automation into a self-aware, data-driven ecosystem.

9. Conclusion

As the wave of industrial automation continues to reshape global manufacturing, drag chain technology has quietly evolved from a passive protector into an intelligent enabler of motion. Its transformation—driven by innovations in material science, digital integration, and sustainability—reflects the broader journey of modern industry toward precision, connectivity, and efficiency.

From high-speed robotic arms to long-travel gantry systems, from cleanroom environments to heavy-duty production lines, drag chains ensure that energy, data, and fluids move reliably and safely where they are needed.

In the future, as automation grows smarter and more connected, the drag chain will remain a vital backbone of industrial mobility—no longer just a mechanical accessory, but a key player in the intelligent machinery of tomorrow.