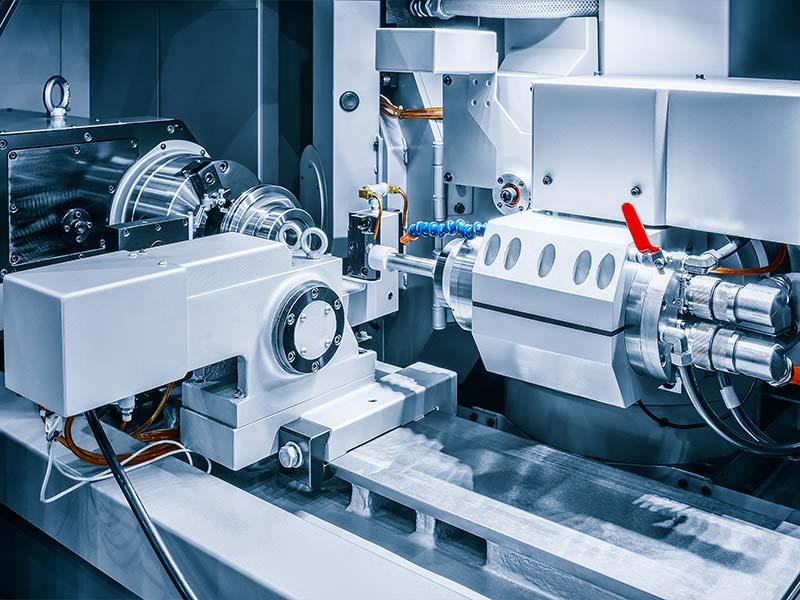

In the fast-paced world of modern manufacturing, safety and reliability are inseparable from productivity. Machine safety has evolved from being a regulatory obligation to a fundamental element of operational excellence. Among all protective components, the machine tool guard plays a particularly vital role — shielding operators from moving hazards while protecting the precision components of machines from damage.

However, choosing the right type of guard can be challenging. There are flexible bellows covers, rigid steel telescopic covers, roll-up shields, and various other forms, each designed for different working conditions. This article provides a comprehensive guide to help you choose the ideal machine tool guard for your equipment — balancing safety, durability, and efficiency.

1. Understanding the Role of Machine Tool Guards

Machine tool guards are protective systems designed to separate operators from hazardous moving parts and to shield sensitive machine elements from dust, chips, and coolant. Their main purposes include ensuring personal safety, preventing contamination, extending machine life, and maintaining a clean and professional workspace.

A good guard should not only protect but also integrate seamlessly with the machine’s function. It must move smoothly with the machine’s motion, withstand mechanical stress, and resist damage from heat, oil, and metal chips. In short, it ensures safe operation without sacrificing performance.

2. Main Types of Machine Tool Guards

Different guards are designed for specific machine types and operating environments. The most common categories include:

Bellows Covers – Also known as flexible way covers, these are typically made from high-strength synthetic fabrics or heat-resistant materials, often reinforced with steel or aluminum frames. Their accordion-like design allows them to expand and compress smoothly. Bellows covers are ideal for protecting linear motion parts such as guideways, ball screws, and measuring devices. They are lightweight, customizable, and effective in keeping out oil and metal chips.

Steel Telescopic Covers – Constructed from overlapping steel plates, telescopic covers provide rigid and durable protection for heavy-duty machines. They are commonly used on CNC machining centers, milling machines, and lathes. These covers are particularly effective in chip-intensive environments and can be equipped with damping systems or wipers to enhance chip removal and reduce noise.

Roll-Up Guards – These guards use a spring-loaded mechanism to retract automatically when not in use. They are compact, easy to install, and suitable for smaller openings or equipment with limited space. Roll-up guards can be made from stainless steel or industrial fabric and are frequently used on small lathes, assembly lines, and testing stations.

Apron Covers – Sometimes called lamella covers, these are made from thin overlapping metal segments, offering protection without the bulk of full telescopic covers. They are lighter, more flexible, and suitable for horizontal applications where chip exposure is moderate.

Cable and Hose Carriers (Drag Chains) – While not traditional guards, drag chains serve a similar purpose by protecting and guiding cables and hoses during movement. They prevent tangling, abrasion, and premature wear, and are essential in automation systems, robotics, and machine tools with multiple moving axes.

3. Factors to Consider When Selecting a Machine Guard

Choosing the right guard involves evaluating your machine’s characteristics, the working environment, and operational needs. Here are the most important factors to consider:

Machine Type and Motion

Different machines move in different ways — some linearly, others rotationally. A flexible bellows is ideal for fast-moving linear axes, while a steel telescopic guard may be necessary for heavy-duty horizontal slides. For rotating spindles, a round or conical bellow can offer 360-degree protection.

Working Environment

If the machine operates in an environment full of metal chips, coolant, or abrasive dust, choose a guard that provides complete sealing and resistance to oil and heat. For cleanrooms or electronics manufacturing, dust-free and anti-static materials are preferred.

Speed and Frequency of Motion

High-speed machines require lightweight and low-friction covers to avoid additional motor load. Heavy, slow-moving machines can accommodate thicker and more rigid materials.

Available Space

The available installation space often determines the guard structure. Compact roll-up or apron covers are suitable for limited spaces, while large telescopic guards require adequate clearance to expand and retract.

Maintenance and Accessibility

A good guard should allow easy maintenance and inspection. Designs that can be detached or replaced quickly help reduce downtime during repair or cleaning.

Compliance with Safety Standards

Always ensure your guards meet relevant industrial safety standards such as ISO 23125 or OSHA machine safety guidelines. Proper design and installation not only protect workers but also help with certification and auditing.

4. Choosing the Right Material

Material selection directly affects the performance, appearance, and lifespan of your machine guard.

For light-duty applications, synthetic fabrics like PVC, nylon, or coated fiber offer flexibility and chemical resistance. These materials are excellent for bellows and roll-up covers used in environments with moderate oil and chip exposure.

For high-load and high-temperature applications, metal guards are a better choice. Stainless steel and carbon steel provide superior impact resistance and are suitable for telescopic and apron covers used on machining centers and lathes.

Aluminum is another popular option, offering a balance between strength and lightness, while composite materials combine the best of both worlds — flexibility with structural integrity.

When selecting materials, consider environmental exposure, operating temperature, and the types of cutting fluids or chips that may come in contact with the guard.

5. Installation and Maintenance Tips

A well-chosen guard can still fail prematurely if installed or maintained incorrectly. To ensure long-term performance, follow these best practices:

- Align the guard precisely with the machine’s moving parts. Misalignment causes friction, noise, and premature wear.

- Use durable mounting brackets and fittings to prevent vibration or loosening during operation.

- Keep the guard clean. Remove chips, oil, and coolant regularly to avoid buildup that could hinder motion.

- Inspect flexible covers for cracks or tears and replace damaged sections immediately.

- For metal guards, lubricate sliding joints periodically to ensure smooth movement and quiet operation.

Preventive maintenance not only extends the life of the guard but also reduces unexpected machine downtime.

6. Customization and Design Flexibility

Every machine tool has unique dimensions, stroke lengths, and movement patterns. That’s why many manufacturers offer custom-made guards.

Customization options include size, material, opening direction, frame type, sealing level, and even surface finish. Reinforced rings, anti-collision buffers, and integrated sensors can also be added for special requirements.

A customized guard ensures perfect fitment, consistent appearance across multiple machines, and better overall protection. It also enhances operator comfort and confidence, contributing to smoother workflow and reduced maintenance time.

7. Balancing Cost and Value

Price is often a decisive factor, but focusing solely on initial cost can be misleading. A cheap, low-quality guard may fail quickly, leading to costly downtime, machine damage, or even safety incidents.

Instead, consider the total cost of ownership — the long-term value provided by reliability, durability, and reduced maintenance needs. Investing in a well-designed guard from a reputable supplier ensures stability, compliance, and fewer unexpected failures.

In the long run, a premium protective system is an investment in safety, productivity, and brand reputation.

8. The Future of Machine Guarding

As the manufacturing industry moves deeper into the era of Industry 4.0, machine guarding is also becoming smarter and more sustainable.

Innovations such as sensor-equipped covers can now detect collisions, wear, or overheating. Modular designs allow for quick replacement without disassembling the entire system. Meanwhile, the use of eco-friendly materials helps reduce environmental impact while maintaining performance.

These trends reflect a broader shift toward intelligent, adaptive protection systems that not only ensure safety but also support digital monitoring and predictive maintenance — helping factories become safer, cleaner, and more efficient.

9. Matching the Guard to the Application

Each machine has its own working characteristics, and the choice of guard should reflect that.

A CNC lathe that generates heavy metal chips requires a steel telescopic cover for maximum impact resistance. A laser cutting machine, by contrast, benefits from lightweight, dust-proof fabric bellows that ensure clean and flexible motion.

Medium-duty milling machines may use apron covers for compact protection, while robotic systems typically rely on drag chains to manage cables and hoses safely.

The principle is simple: match the guard to the working load, speed, and environmental challenge.

10. Conclusion

Selecting the right machine tool guard is not just about compliance — it’s about protecting your people, your machines, and your reputation. A well-designed guard can dramatically improve workplace safety, reduce maintenance costs, and extend the lifespan of expensive equipment.

When choosing, consider how your machine operates, what conditions it faces, and how often it moves. Then select the appropriate design and material that provide durable protection without interfering with performance.

Whether it’s a flexible bellow cover for a CNC machine or a robust steel telescopic guard for a machining center, the right choice will ensure smooth operation, maximum safety, and long-term value.