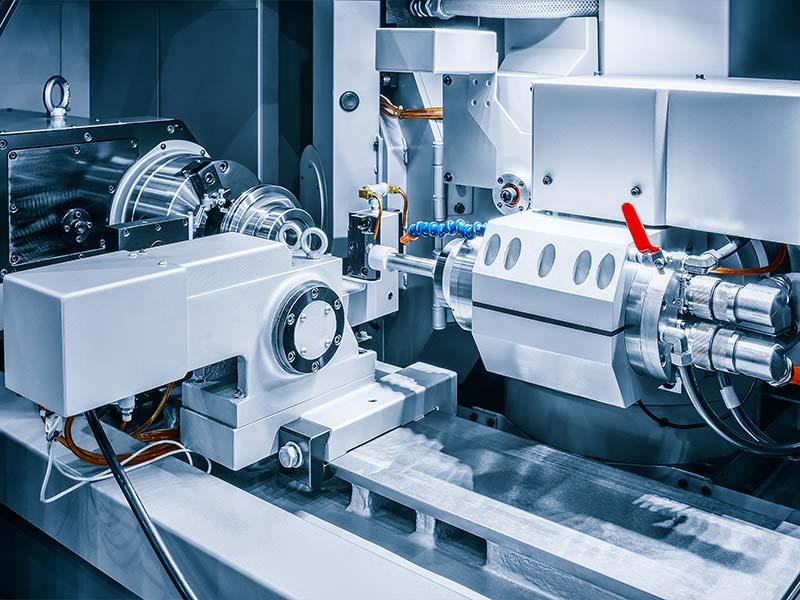

In modern mechanical equipment, the lead screw plays a vital role as a transmission component, responsible for converting rotational motion into precise linear motion. To maintain the high efficiency and accuracy of this motion, the screw must be protected from dust, metal chips, oil, and other contaminants that can cause wear or damage. This is where the lead screw protective cover—also known as a bellows cover or screw guard—comes into play.

This article explores in detail the working features, structural principles, material options, and industrial applications of lead screw protective covers, offering a comprehensive understanding of why they are essential in CNC machinery and automated systems.

1. The Fundamental Purpose of a Lead Screw Protective Cover

A lead screw protective cover is designed to isolate the lead screw from external contaminants while allowing free and smooth operation. Its main functions include preventing dust and chips from entering the transmission area, resisting the penetration of cutting fluids or corrosive chemicals, ensuring operator safety by shielding rotating parts, and prolonging the life of the screw by maintaining a clean and lubricated working environment.

In CNC machines, automation lines, measuring instruments, and industrial robots, the lead screw cover serves as a critical protective element that ensures long-term precision and stability of the system.

2. Main Working Features

The most distinctive feature of a lead screw protective cover is its ability to expand and contract along with the movement of the lead screw. Whether installed vertically or horizontally, it can maintain its shape and function without restricting the motion of the machine.

First, it performs flexible telescopic motion. The bellows-like design allows the cover to stretch and compress in coordination with the movement of the screw. Each fold section expands or collapses smoothly, ensuring full coverage throughout the entire stroke. This makes it possible to tailor the cover’s total extension length and compression ratio according to specific machine dimensions or travel distances.

Second, it is suitable for both vertical and horizontal installation. When used vertically, the protective cover naturally extends downward under its own weight, maintaining an ideal form without additional support. When used horizontally, plastic or aluminum support rings are often installed inside the bellows to prevent sagging and to keep a consistent gap between the inner cavity of the cover and the screw surface. This structural detail prevents friction, reduces vibration, and significantly extends service life.

Third, the cover’s stability can be enhanced with metal reinforcement rings. When the stroke length is large, adding a reinforcing ring inside each fold improves resistance to deformation and prevents the cover from collapsing or swaying during rapid movement. This stability is especially important for high-speed CNC machines where any imbalance could affect precision and performance.

Finally, the connection method is highly adaptable. Depending on the installation requirements, the ends of the cover can be secured using metal flanges for a firm, permanent attachment or clamp-type collars for easier replacement and maintenance. The choice depends on whether the machine demands quick disassembly or a more rigid, vibration-resistant connection.

3. Structural Composition and Material Characteristics

A lead screw protective cover is generally composed of three main parts: the outer protective material, the internal support structure, and the connecting elements.

The outer material can vary depending on the working environment. Common choices include PVC-coated fabric, nylon, rubber, synthetic leather, or multi-layer composite fabrics known as “three-proof cloth,” which are resistant to water, oil, and corrosion. For high-temperature or heavy-duty conditions, stainless-steel or galvanized steel plate bellows can be used instead of flexible fabric. Each material offers different advantages in terms of durability, chemical resistance, and flexibility.

The support structure inside the cover plays a key role in maintaining its form. Plastic or aluminum support rings are spaced evenly along the folds to prevent collapse and keep a stable internal clearance. In some cases, metal reinforcement rings are added between folds to increase rigidity and allow the cover to maintain its shape even under pressure or rapid movement.

The connecting components—such as flanges, clamps, or end caps—are typically made of steel or aluminum and can be customized according to machine design. Precision in these parts ensures that the cover aligns concentrically with the lead screw, reducing the risk of misalignment or interference during operation.

4. Advantages of Using a Lead Screw Protective Cover

The primary advantage of installing a lead screw protective cover lies in its ability to safeguard key transmission elements from environmental hazards. By preventing dust, chips, and coolant from entering the screw assembly, the cover minimizes friction and surface damage. This protection directly translates into longer service life, smoother motion, and reduced maintenance frequency.

Another important benefit is the wide adaptability of the design. The same cover can be used in vertical, horizontal, or inclined installations with minimal modification. This versatility makes it a universal solution for various types of equipment.

The stability and smoothness of operation are further enhanced by the inclusion of support rings and reinforcing bands. These prevent excessive deformation during high-speed movement, ensuring that the protective cover moves uniformly with the screw without vibration or noise.

Ease of maintenance is also a key feature. The cover can be detached quickly using clamping rings or bolts, allowing technicians to inspect and clean the screw system without dismantling major components. This convenience reduces downtime and lowers maintenance costs.

Finally, due to its fatigue-resistant and abrasion-resistant design, the lead screw protective cover can operate reliably over long periods even in harsh industrial environments, contributing to overall machine longevity and safety.

5. Typical Applications

Lead screw protective covers are used across a wide range of industrial and automation systems. In CNC lathes and machining centers, they protect precision ball screws from chips and coolant, ensuring consistent machining accuracy. In automated production lines, they shield linear motion systems from dust and debris, maintaining stable and efficient operation.

In measuring and inspection equipment, where precision is critical, the cover ensures that the screw remains clean and free from contamination that could distort readings. In industrial robots, lead screw or actuator covers safeguard drive mechanisms during repetitive, high-speed movements. Additionally, logistics and material handling systems use these covers to protect actuators and guide screws from environmental exposure during continuous motion.

Through these applications, the lead screw protective cover demonstrates its indispensable role in improving reliability, safety, and performance across diverse industrial sectors.

6. Usage and Maintenance Recommendations

To ensure optimal performance and extended service life, several maintenance practices are recommended. The protective cover should be cleaned regularly to remove accumulated oil, dust, or metal shavings. Any hardened residues should be wiped off gently to avoid damaging the surface coating. During installation, the maximum extension should not be exceeded; sufficient slack must be left to prevent overstretching or tearing under load.

It is also essential to inspect the internal support rings periodically. If a ring breaks or becomes deformed, it should be replaced immediately to prevent the cover from sagging or contacting the lead screw. The installation alignment should be checked to ensure that the flanges or clamps are concentric with the screw axis; misalignment can lead to twisting or uneven wear during motion.

In environments with high temperature, heavy coolant exposure, or chemical corrosion, selecting a material specifically designed for those conditions is crucial. Specialized fabrics with heat resistance or acid-alkali protection can greatly improve durability.

By following these guidelines, users can maintain stable operation, protect their machine’s precision components, and minimize unexpected failures.

7. Conclusion

Although a lead screw protective cover might appear to be a small accessory, its role in the overall reliability and longevity of industrial machinery is profound. It acts as both a physical barrier and a precision safeguard, ensuring that transmission components perform flawlessly even in demanding working conditions.

As manufacturing technology continues to advance toward higher speed, accuracy, and automation, the quality and design of machine protection components have become increasingly important. A well-engineered protective cover reflects not only mechanical ingenuity but also a company’s commitment to detail, precision, and long-term performance.

By understanding its working features, structural design, and maintenance principles, engineers and machine operators can fully utilize the benefits of the lead screw protective cover—maintaining cleaner, safer, and more reliable production environments for years to come.